planet

manufacturing footprint + carbon

Our Approach

We remain committed to owning our manufacturing and supply chain as it affords us greater control to push sustainability forward.

our progress

Carbon Disclosure Project (CDP)

5%

annual reduction of our carbon emissions is our priority, and we have committed to set a science based target through the Science Based Targets initiative

Manufacturing Initiatives to Reduce Footprint

• Green Impact Program

• Natural Gas + Electricity Initiatives

• Manufacturing Locally for the Market

• Packaging

• Pallet Program

• Material Recovery + Re-use

• Reducing Transportation + Textile Waste

50,000

tie wraps diverted per year from our waste stream at our Quebec facilities by switching to re-useable belts

97%

less space is used by Optiledge pallets compared to traditional wood pallets

Textile waste is baled

and sent to other manufacturers to be used as filler

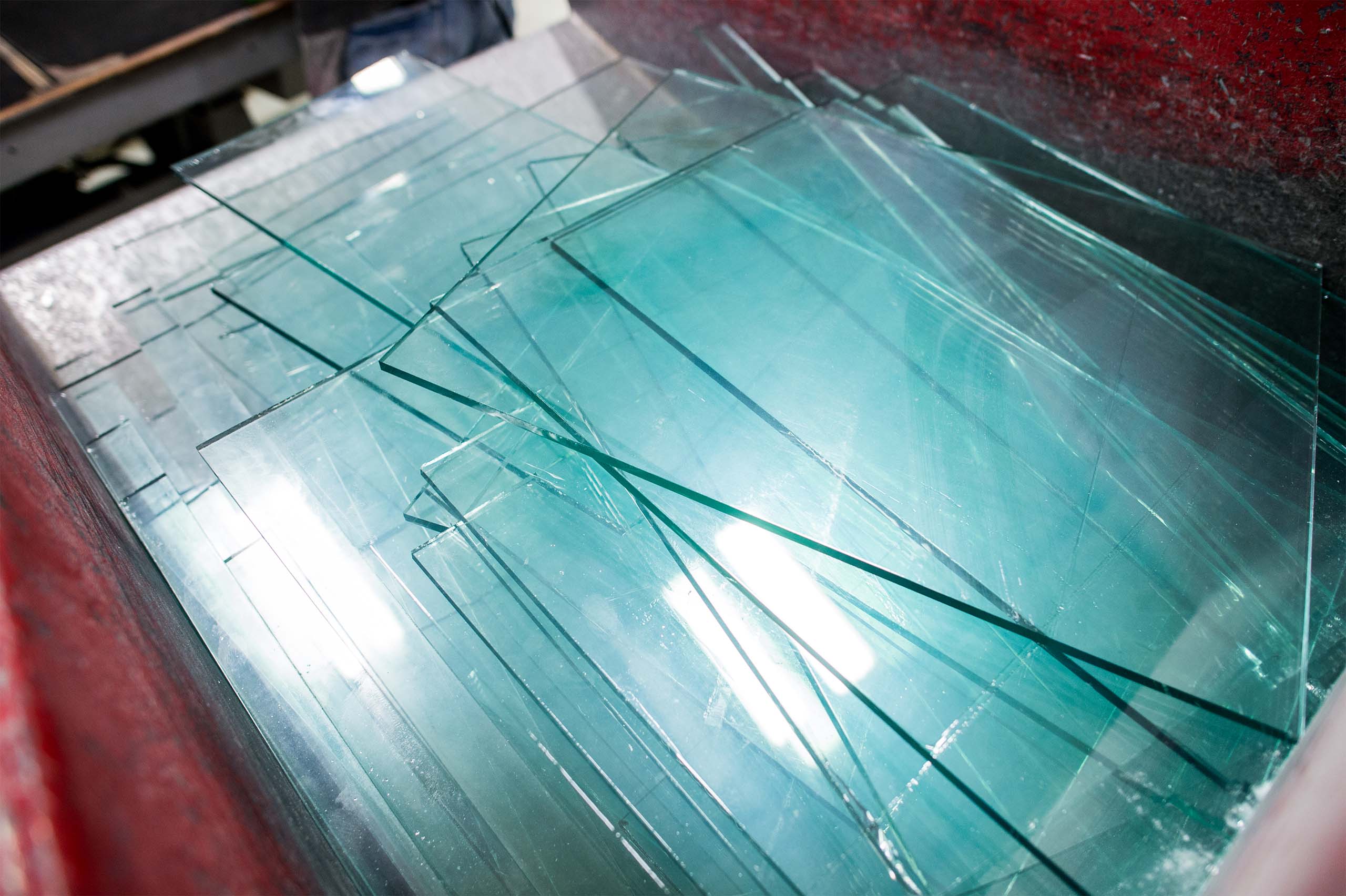

369 tonnes

of waste diverted, 18 tonnes of CO2 avoided

and $29,200 in savings realized by transforming

laminated glass scraps into abrasive products

we recycle

on average 75,000 kg of tempered glass and 60,000 kg of laminate glass per month into abrasive products

belonging + inclusion

Creating places where people feel valued, included and where they feel that they belong.

employee + community wellbeing

Strengthening all our communities, internally and externally.

manufacturing footprint + carbon

Minimizing the impact of our activities on the environment.

product

materiality + lifecycle

Ensuring material transparency and minimizing toxicity across our entire product offering.